Aluminum

Aluminium

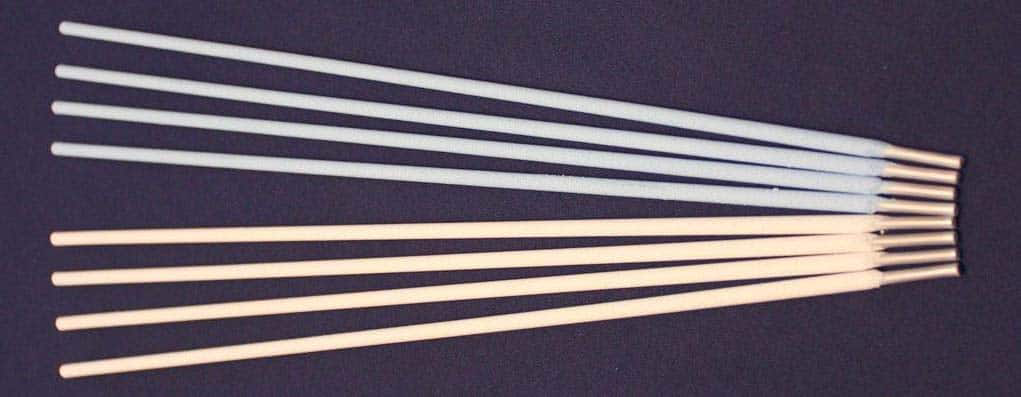

Our premium range of aluminium welding consumables, including MGS – 371, 372, 373, 374, and 4043 grades, are designed to deliver excellent strength, corrosion resistance, and smooth weldability. Widely used across industries such as automotive, construction, and fabrication, these aluminium alloys ensure reliable performance in both general and critical applications. At Weld Delco Alloys Pvt. Ltd., we provide high-quality aluminium solutions trusted by professionals in New Delhi and across India, backed by our expertise in welding materials and commitment to customer satisfaction.

MGS 371 - AluminIum

Arc Welding Aluminums Alloyed With Manganese And Magnesium. Also Excellent For Joining Dissimilar Grades Of Aluminum And For Seawater Applications And Aluminum Arc Welding Electrode With Exclusive Self Lifting Slag. Unique Self Lifting Slag.Pure White Long Shelf Life Extruded Flux Coating Outlasts Conventional Products In Moisture Resistance.

Available In Vacuum Sealed Packing For Extended Shelf Life.

MGS 372 - aluminIum

Repairing All Brazable Aluminum Castings – Filling In Holes, Building Up Worn Or Missing Sections And Joining Cast To Wrought Parts.

General Purpose Outdoor Use On Repairing Aluminum Skids, Platforms, Loading Docks, Truck Bodies, Irrigation Piping, Fences And Railings.

Flux Residue Washes Off Easily With Warm Water

Available In Vacuum Sealed Packing For Extended Shelf Life.

MGS 373 - aluminIum

Arc Welding Aluminums Alloyed With Copper, Silicon, And Magnesium. Also Excellent For Joining Dissimilar Grades Of Aluminium And 5% Silicon Aluminum Arc Welding Electrode With Exclusive Self Lifting Slag.

Unique Self Lifting Slag.Pure White Long Shelf Life Extruded Flux Coating Outlasts Conventional Products In Moisture Resistance.

Available In Vacuum Sealed Packing For Extended Shelf Life.

MGS 374 - aluminIum

Arc welding aluminums alloyed with copper, silicon, and magnesium. Also excellent for joining dissimilar grades of aluminum.

12% Silicon aluminum arc welding electrode with exclusive self lifting slag. Unique self lifting slag.Pure white long shelf life extruded flux coating outlasts conventional products in moisture resistance. Available in vacuum sealed packing for extended shelf life.

MGS 375 - aluminIum

Arc welding aluminums alloyed with copper, silicon, and magnesium. Also excellent for joining dissimilar grades of aluminum.

12% Silicon aluminum arc welding electrode with exclusive self lifting slag. Unique self lifting slag.Pure white long shelf life extruded flux coating outlasts conventional products in moisture resistance. Available in vacuum sealed packing for extended shelf life.

MGS 376 - aluminIum

Arc welding aluminums alloyed with copper, silicon, and magnesium. Also excellent for joining dissimilar grades of aluminum.

12% Silicon aluminum arc welding electrode with exclusive self lifting slag. Unique self lifting slag.Pure white long shelf life extruded flux coating outlasts conventional products in moisture resistance. Available in vacuum sealed packing for extended shelf life.

MGS 378 - aluminIum

Arc welding aluminums alloyed with copper, silicon, and magnesium. Also excellent for joining dissimilar grades of aluminum.

12% Silicon aluminum arc welding electrode with exclusive self lifting slag. Unique self lifting slag.Pure white long shelf life extruded flux coating outlasts conventional products in moisture resistance. Available in vacuum sealed packing for extended shelf life.

MGS 4043 - aluminIum

Joining Aluminum Extrusions Used In The Manufacture And Repair Of Aluminum. Also For Repairing Leaders, Gutters, Siding, Aluminum Boats And Instrument Boxes. Most Kirksite And Zinc Base Die Castings Can Be Repaired With This Alloy. Can Also Be Used as a Wearfacing Alloy On Aluminum. Maximum Strength, Self Fluxing Solder For Joining, Build-Up And Hardfacing Aluminum. High Zinc Content Gives Good Color Match To Aluminum.

Low Working Temperature Prevents Warpage, Distortion And Discoloration.